Manufacturers invest in ERP to tighten planning, speed production, and control costs. But ERP projects too often become long, costly, and disruptive — especially for mid-market and fast-growing manufacturers.

Below are the five common pain points we see in the manufacturing industry, and the pragmatic ways Odoo addresses them so you get value fast.

1. Long implementations and scope creep

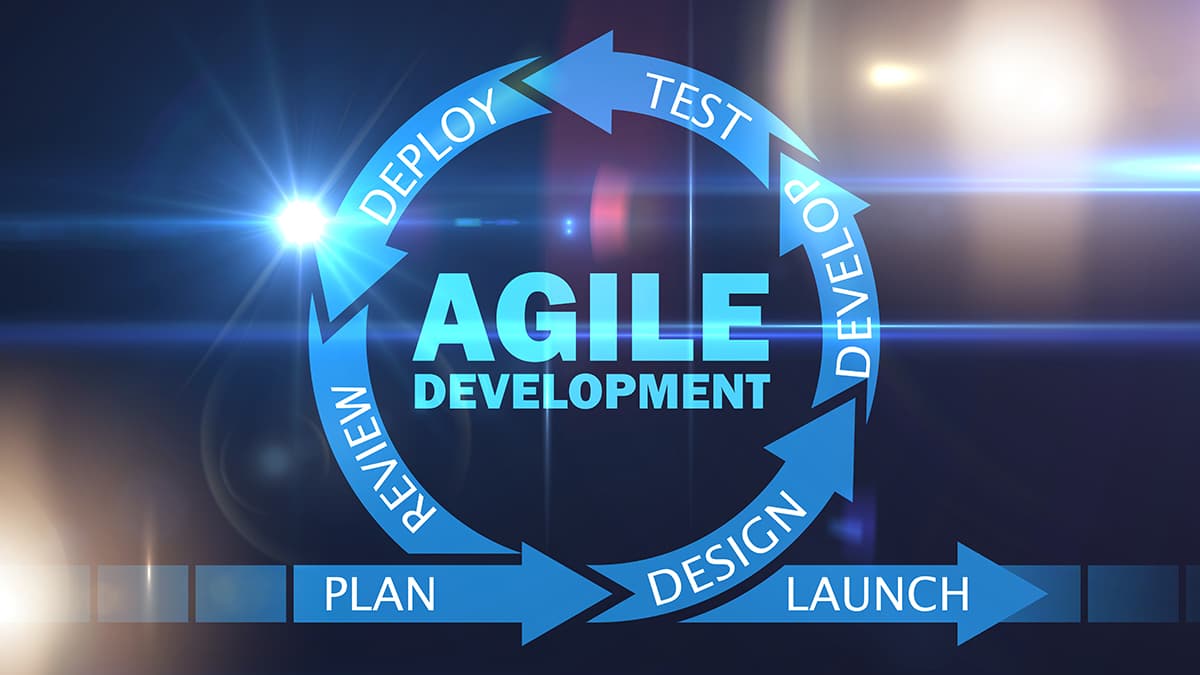

The problem: Projects expand — new requirements, custom features, extra integrations — and what started as a 6-month plan stretches into a year or more. That delays benefits, inflates cost, and creates stakeholder fatigue.

Why it matters: Delayed go-live means delayed ROI, continued manual workarounds, and lost opportunity to optimize operations.

How Odoo helps:

- Modular rollout: Deploy core MRP, Inventory, and Accounting first; add Quality, Maintenance, or MES later. This staged approach locks down scope and delivers early wins.

- Configure before you customize: Many manufacturing workflows map to Odoo’s out-of-the-box features (BoMs, routings, work centers). That reduces custom development and keeps timelines short.

2. Poor data quality and messy migrations

The problem: Legacy systems + spreadsheets = inconsistent item masters, wrong stock balances, and bad supplier data. Bad data breaks planning and undermines trust in the new ERP.

Why it matters: Production delays, excess safety stock, and poor supplier performance all hit margins.

How Odoo helps:

- Structured import tools: CSV importers and guided templates speed clean data migration for products, BoMs, and inventory balances.

- Single data model: Odoo links MRP, Inventory, Purchasing, and Accounting so item, lot, and serial data flow end-to-end — reducing reconciliation work and errors.

3. Limited shop-floor visibility and unexpected downtime

The problem: Without real-time visibility into work orders, machine status, and WIP, bottlenecks and unplanned downtime cascade through production.

Why it matters: Every hour a line sits idle costs money — sometimes a lot. Poor visibility makes it impossible to prioritize fixes or reroute work quickly.

How Odoo helps:

- Work orders + capacity planning: Odoo schedules operations against work centers and available capacity to reduce overloads.

- Maintenance integration: Preventive maintenance is tied to equipment records — fewer surprises, less emergency downtime.

- Operator inputs: Tablet/kiosk inputs capture start/stop, scrap, and notes so supervisors see WIP and act fast.

Quick reality check: Unplanned downtime is expensive — recent analysis estimates the world’s 500 largest companies lose roughly $1.4 trillion annually from unplanned downtime (about 11% of revenues). In some manufacturing segments, an hour of downtime can cost millions.

4. Inventory accuracy, traceability, and cost control

The problem: Inaccurate counts and weak traceability tie up cash and increase compliance risk. Planners struggle with reorder points, and recalls or audits become costly manual exercises.

Why it matters: Excess inventory strains working capital; poor traceability risks regulatory fines and reputational damage.

How Odoo helps:

- Smart replenishment: Min/max rules, lead-time aware reorder points, and MTO/MTS strategies reduce excess stock and stockouts.

- Full lot/serial traceability: Materials tracked from receipt through production to shipment, simplifying audits and recalls.

- Integrated Quality & PLM: Quality checks and versioned BoMs keep control over changes and defects — cutting rework and scrap.

5. User adoption and change resistance

The problem: People resist change. If the new system isn’t easy or stakeholders aren’t engaged, processes degrade and the ERP becomes a compliance box rather than a business tool.

Why it matters: Low adoption negates the investment — processes stay manual and performance doesn’t improve.

How Odoo helps:

- Intuitive UI and role-based views: Users access simplified screens tailored to their job — planners see planning, operators see work orders, accountants see journals. That shortens training time.

- Phased rollout and train-the-trainer: Start with a pilot, train power users, then scale. Iterative rollout reduces shock and improves uptake.

ERP program outcomes still challenge many organizations: independent industry studies show a meaningful portion of ERP projects fail to meet objectives on the first attempt — highlighting why a measured, business-first approach matters.

How to structure a low-risk manufacturing ERP project?

- Define the must-have value: Prioritize the processes that will improve cash flow or production efficiency within 90 days.

- Phase delivery: Go live with core planning, inventory, and procurement; add advanced modules after stabilization.

- Fix the data: Treat data cleanup and migration as project-critical workstreams.

- Instrument the shop floor: Simple operator inputs and preventive maintenance give disproportionate returns.

- Invest in adoption: Short role-based training sessions, quick reference guides, and an internal support squad keep momentum.

.jpg)

Final thought

Manufacturing ERP projects don’t have to be risky or expensive: the right platform and the right delivery model change the equation. Odoo’s modular architecture, modern UI, and integrated manufacturing apps make it a practical choice for manufacturers that want to lock scope, deliver fast, and scale capability without ballooning cost.

Pair the platform with disciplined governance, clean data, and a shop-floor focus — and you get an ERP project that pays back, not a project that stalls.

Ready to get started?

If your organization is planning an Odoo ERP project — or struggling with an existing implementation — CSM Tech can help. Our Odoo experts bring deep industry knowledge, proven delivery frameworks, and hands-on consulting to ensure your ERP drives real business outcomes.

Contact us today to explore how we can accelerate your Odoo journey.

Want to start a project?

Get your Free ConsultationOur Recent Blog Posts

© 2026 CSM Tech Americas All Rights Reserved