Innovating with Excellence

Empowering governments across Africa with cutting-edge technology solutions. As the organization specializing in African government digital transformation, CSM Tech Africa delivers unparalleled quality and reliability for mission-critical government projects across East Africa.

Awards

- Disclosure of Asset Registration System

- Property Tax Management System

- Workflow Automation System

- Single Window System

- Integrated Land Management System

- Soil Information System

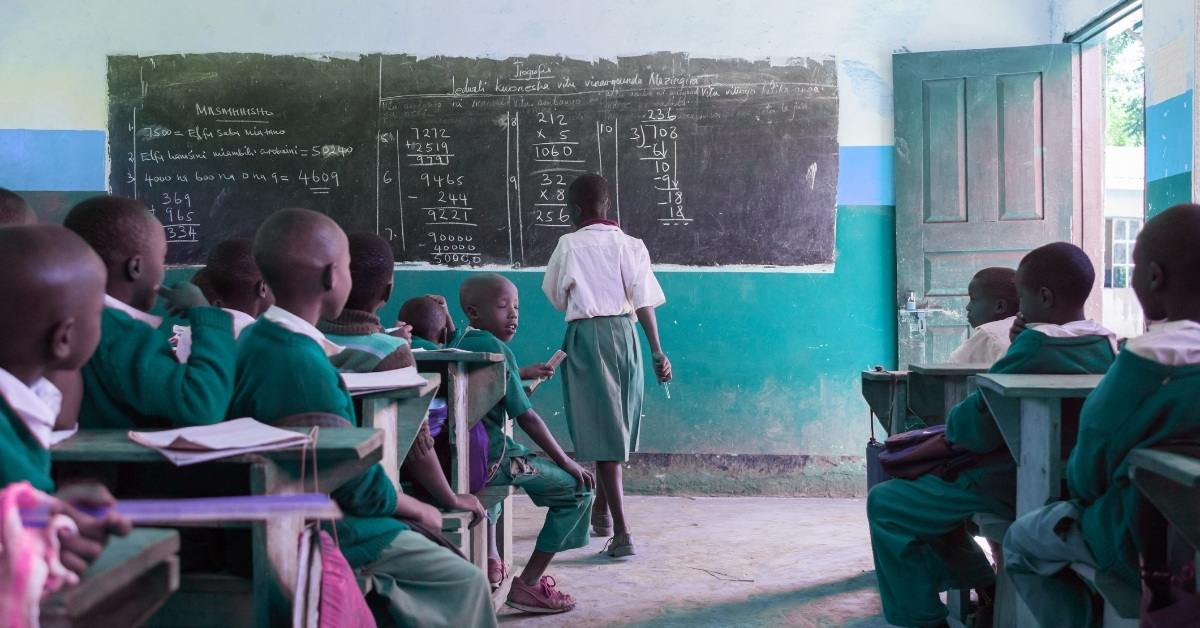

- School Mapping System

- Integrated Beneficiary Management System

- Early Warning and Pest Monitoring System

- City Level Program Monitoring

- E-Commerce Design

- Digital Media Library Platform (DMLP)

Process Maturity

Process Maturity Data Security

Data Security Quality Management

Quality Management Information Security

Information Security Service Excellence

Service Excellence Sustainability

Sustainability HR Excellence

HR Excellence People Excellence

People ExcellenceComprehensive Government Solutions Across Africa

Empowering governments across Africa with cutting-edge technology solutions. As the organization specializing in African government digital transformation, CSM Tech Africa delivers unparalleled quality and reliability for mission-critical government projects across East Africa.

Explore all Solutions

Comprehensive Service Offerings

AI and Allied Services

Applied AI technologies that help organizations automate decisions, scale intelligence, and create measurable impact.

Consulting and Allied Services

Strategic and execution-focused support helping organisations navigate change and align technology with business goals.

Data and Analytics

Data and analytics services that turn growing data into timely insights organisations can trust and act on.

Emerging Technologies

Emerging technologies that help organisations understand digital signals, respond faster, and build trust at scale.

Engineering, Application and Transformation

Engineering and application development services that modernize systems, streamline operations, and enable digital transformation at scale.

IT Facilities, Cybersecurity and Partner Services

Secure IT infrastructure and cybersecurity services that keep systems resilient, available, and ready to scale.

Transformation Stories & Research from the Field

Research, insights, and best practices from 25+ years transforming African government operations.

Let’s Build Digital Africa,Together

Whether you’re a government body, public enterprise, or development partner, we’re here to collaborate on transformative digital initiatives.

Talk to our Experts

Connect with our experts to explore tailored digital solutions that fit your goals and challenges.

Request a MeetingRequest for Service

Let’s connect to discuss your needs and craft the right digital solution together.

RequestTransform Africa's Future While Building Yours

Join our growing team to work on projects that directly impact 50 million+ citizens across Kenya, Rwanda, Tanzania, Uganda, and Ethiopia.