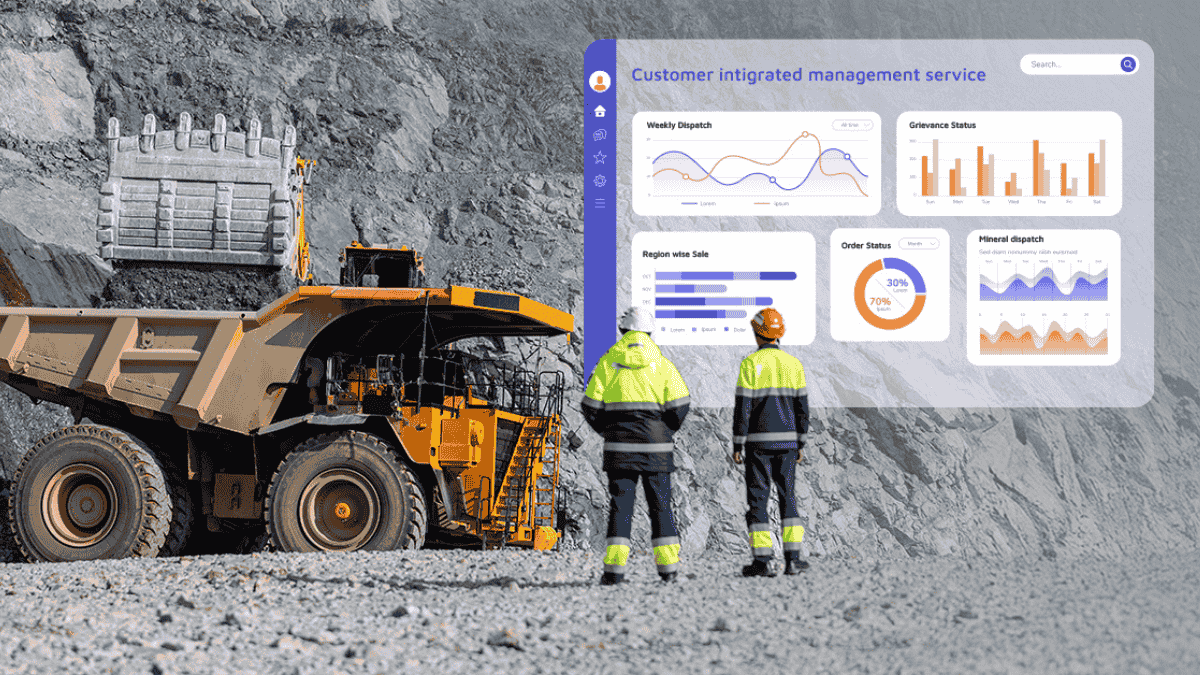

Mineral dispatch doesn’t start on the highway; it begins at the source, inside the mines. Before any truck exits a mining area, it passes through multiple in-mine verification points equipped with weighbridges and digital validation systems. These checkpoints ensure that the vehicle’s mineral load, declared weight, documentation, and destination details are accurate and compliant before the truck is allowed to exit. These source-level checks form the first line of defence in ensuring that the right grade and quantity of minerals leave the mine.

But the real challenge emerges after the truck leaves the mines. Once it enters the open road, the level of scrutiny drops significantly, exposing the entire supply chain to risk.

From the mine to the destination, most mineral transportation happens on long stretches of road where surveillance is minimal or nonexistent. This unmonitored section becomes the most vulnerable part of the mineral corridor. Certain transporters and intermediaries take advantage of this gap, exploiting policy loopholes, manipulating documents, or altering loads during transit—activities that often go undetected due to the absence of real-time oversight. Despite several government measures over the years, the lack of continuous monitoring has made fraud easier, emboldening bad actors and resulting in significant revenue leakage. When lakhs of metric tonnes move across the state every day, even minor manipulation or a small percentage deviation accumulates into heavy financial losses for the government.

This mid-transit vulnerability is exactly why public checkpoints are critical in the overall mineral governance framework.

(1).jpg)

The Role of Public Checkpoints as Mid-Transit Verification Points

Government-manned public checkpoints equipped with weighbridges were conceived as mid-transit control points, designed to revalidate the truck’s details before it reaches its destination. They act as the only physical touchpoints between the point of dispatch and the point of delivery where discrepancies can be caught in real time. However, historically these checkpoints relied heavily on manual operations—handwritten logs, inspector judgments, and physical inspection methods. Such manual processes left room for inconsistencies, delays, and inaccuracies, making it difficult to ensure complete transparency and compliance.

Recognizing the risks associated with manual interventions, the state prioritized the modernization of these checkpoints to improve reliability and reinforce the governance structure.

Government Modernization Efforts and CSM’s Role

With mineral movement increasing every year and the operational risk growing, the government initiated a state-wide modernization plan focused on upgrading public checkpoints and their weighbridge systems. The goal was to establish an automated, objective, and tamper-resistant verification mechanism capable of eliminating human errors and ensuring consistent validation across all locations.

CSM Technologies, as the system integrator, implemented the mineral checkpoint monitoring system across public checkgates, bringing automation, transparency, and data integrity into the mineral dispatch workflow. These enhancements transformed the role of checkpoints from being simple weighing posts to becoming crucial digital governance touchpoints.

Public checkpoints have always been important for mineral compliance, but their effectiveness was limited by manual processes. As dispatch volumes grew, manual methods struggled with inconsistent documentation, subjectivity in decision-making, and slow verification cycles.

The modernized checkpoints now function as digital governance hubs. They operate as automated, interconnected validation centres where the data of each truck is synchronized with central systems like I3MS. This integration ensures that every truck passing through the checkpoint is cross-verified against authoritative records. The enhanced audit trail, combined with automated system checks, creates transparent end-to-end traceability throughout the mineral corridor.

(1).jpg)

How IoT and Emerging Technologies Power the Modern Checkgate

Ensuring compliance mid-transit requires more than simply capturing the vehicle’s weight. It demands reliable identification, tamper-proof validation, and structured digital evidence. This is where IoT plays a transformative role.

Now, every critical device on the weighbridge from weighment instruments and infrared sensors to cameras and automated barriers is connected through IoT, forming a synchronized and intelligent validation environment. Automatic Number Plate Recognition (ANPR) captures the truck’s number plate as soon as it approaches, while CSM’s number-plate enhancement algorithms ensure accurate recognition even in challenging light or weather conditions. High-resolution cameras capture both top-view and front-view images for evidence. Sensors validate alignment and ensure accurate weight capture. Automated checks compare declared load with actual readings, removing the possibility of manual manipulation.

Instead of functioning as independent tools, these IoT-connected devices work together to create a complete digital signature for every truck, replacing subjective manual interpretation with precise, automated validation.

The real value of IoT-enabled weighbridges lies in their ability to support governance with continuous digital monitoring. Every interaction at the checkpoint whether it is number plate capture, weighment, exception detection; everything is automatically converted into structured digital records. These records are instantly synchronized with central data servers and systems such as I3MS, making each transaction verifiable against authoritative datasets.

Authorities now rely on real-time, evidence-backed insights rather than handwritten logs or delayed reports. If any discrepancy occurs, the system detects it immediately and alerts enforcement teams, allowing intervention on the checkpoint itself before the truck proceeds further. This proactive approach significantly reduces revenue leakage and strengthens compliance across the corridor.

With automated validation and consistent data capture, every checkpoint becomes inherently audit-ready. Each captured image, weighment record, and system log forms part of a reliable digital evidence trail. When disputes arise, auditors no longer need to reconstruct events. Every detail is already stored, time-stamped, and traceable within the system, allowing for faster and more transparent audit cycles.

The integration of IoT-enabled weighbridges with centralized platforms provides administrators with real-time visibility across the entire mineral corridor. They can monitor truck movement patterns, identify route deviations, track peak operational hours, and detect irregularities as they occur. This live insight enables quicker interventions and strategic resource allocation, shifting governance from delayed reaction to immediate, data-driven decision-making.

Before modernization, each public checkpoint operated independently with varying standards. With IoT weighbridges installed across multiple locations, the system now functions as a unified compliance network. Verification processes are standardized, data remains consistent, and enforcement becomes uniform across the corridor. As more checkpoints adopt this digital ecosystem, the governance structure becomes increasingly robust, ensuring that every point in the mineral corridor contributes to a synchronized, tamper-proof compliance framework.

The modernization of public checkpoints strengthens trust across the ecosystem. Transporters gain confidence in fair and consistent checks. Authorities depend on objective evidence rather than subjective interpretation. Auditors benefit from structured records, and policymakers rely on accurate data when shaping future regulatory frameworks. Transparency is no longer dependent on people; it is embedded into the digital architecture of the system.

(1).jpg)

Toward a Future-Ready Mineral Dispatch System

IoT-based mineral checkpoint monitoring represents more than a technological upgrade. It reflects a shift toward smarter governance, improved mid-transit control, and consistent policy enforcement. With IoT connectivity, automated validation, digital evidence, real-time synchronization, and integration with systems like I3MS, public checkpoints now operate as strategic enforcement centres within the mineral corridor.

As the system integrator, CSM Technologies has played a critical role in modernizing this essential component of the mining supply chain. These upgraded checkpoints ensure accuracy, transparency, and long-term reliability, forming the backbone of a future-ready mineral dispatch ecosystem.

The future of mineral dispatch is no longer manual or reactive. It is digital, accountable, and built for scale.

We will verify and publish your comment soon.