Industry 4.0 offers the opportunity for manufacturers to optimize their operations by knowing what needs their attention, providing better analysis & insightful maintenance within a reasonable timeframe along with auto-correct. Enhancing the end-to-end performance of the mine-to-market value chain can be a major source of value creation. The mining value chain—which includes everything from extracting raw material to delivering products to customers—is the foundation of the industry. Companies that manage their value chain well can establish a significant source of competitive advantage and value creation. According to the World Bank Group, clean energy needs will escalate the demand for rare earth minerals by nearly 500% by 2050. The fourth industrial revolution holds the key to the world's carbon neutral future. Mining can be the gateway to the world’s carbon-neutral future with its green energy storage systems. While this growing demand holds much promise for mining companies, it also creates new challenges. Technology and proactive maintenance benefits have the potential to transform mining operations, starting with condition monitoring. Mining 4.0, offers the transformation driven by the adoption of automation and digital technologies. It facilitates capabilities such as digitization, automation, analytics, artificial intelligence and machine learning, establishing a powerful foundation for proactive maintenance solutions and innovation. In addition to managing and minimizing the impact of failures, mitigating downtime and reducing maintenance costs, it also helps to increase worker safety, reduce energy consumption and meet environmental requirements.

Logistics processes are the backbone of any profitable mining enterprise and constitute one of the key areas of optimization. Miners face a considerable challenge to manage logistics as mines are usually located in the remote hinterland. And, since logistics in mines use multi-modal transport systems railway rakes, containers, trawlers etc., mining companies need to have end-to-end visibility to ensure that the extracted ore reaches the consumption point in time and avoid the risk of theft in transit. There is a need to integrate the disaggregated modes of communication that results in not only great inconvenience but also an excess cost. India’s PM Gati Shakti - National Master Plan for Multi-modal Connectivity, is essentially a digital platform that brings 16 Ministries including Railways and Roadways together for integrated planning and coordinated implementation of infrastructure connectivity projects.The multi-modal connectivity provides integrated and seamless connectivity for movement of people, goods and services from one mode of transport to another. It will facilitate the last mile connectivity of infrastructure and also reduce travel time for people.

Moreover, it is difficult to distinguish between supply chains, which manage inbound and outbound logistics and warehousing, and value chains, which are made up of integrated end-to-end processes. Historically, comprehensive management of the latter has not been a priority for mining companies. This oversight has resulted in siloed operations (logistics and commercial services) and organizational setups in which responsibilities are distributed to optimize individual steps (mining, processing, rail, or shipping), rather than a comprehensive whole. While preparing to address these tighter regulations, mining companies must significantly reduce their environmental footprint to satisfy the increasing push for disclosure by governments, investors, and stakeholders. To date, the mine-to-market value chain has often been handled within organizational silos, which have limited coordination and real-time data exchange. Understanding the mining value chain as a single integrated process, however, can allow companies to take a truly comprehensive view of performance.

Need for Digitalizing Mine Logistics Chain

The global mining industry has faced unprecedented challenges from COVID-19, volatile commodity prices, and carbon neutrality commitments. Digital innovations in supply chain automation could provide the breakthrough for improvement in mining efficiency and productivity, lowering operating costs, and providing a safer working environment. Robotics Process Automation (RPA) tools and touchless technologies automate routine jobs and bring real-time visibility and control over mining operations. Automation also eliminates duplication of jobs, reduces operating costs, generates advanced data analytics, and frees up time for professionals to focus on decision making, solving problems, and improving communications. Mining companies can optimize the flow of crew, material, and equipment with digital technologies, and innovate and respond faster to supply chain disruptions. The key to unlocking business value is to see innovation as a mindset change supported by process improvements and technology adoption.

Automating the right tasks under logistics can overcome the challenges faced by miners through efficient optimization of the entire supply chain. With a sense of urgency and precision at the heart of this module, the solution caters to the most challenging logistics problems including but not limited to dealing with pilferage, untraceable material movement and porous/opaque movement of mineral carrying vehicles plying within the mining premises. Working hand-in-hand with the modules such as autonomous weighbridges operation, e-Transit pass, Invoice & e-waybill generation process and ERP, the best in class value proposition is guaranteed for any modern-day mining enterprise.

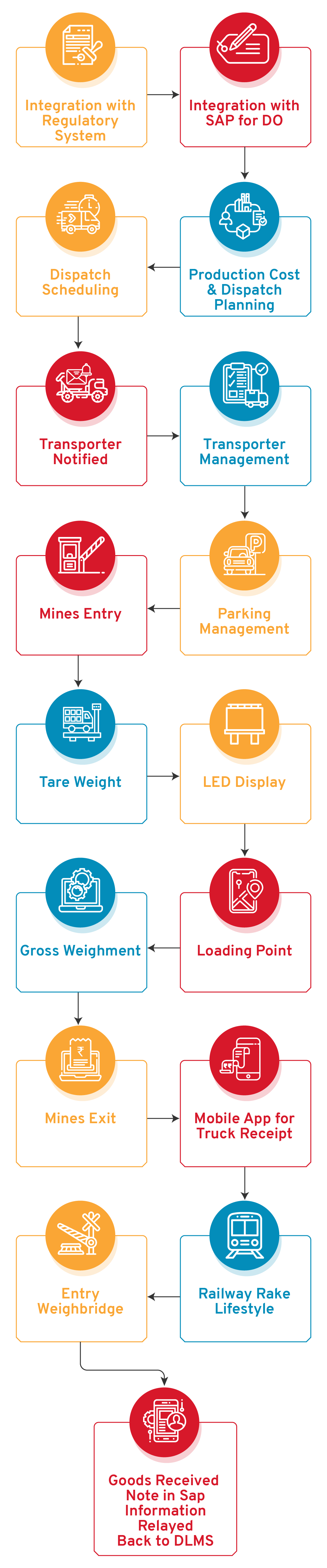

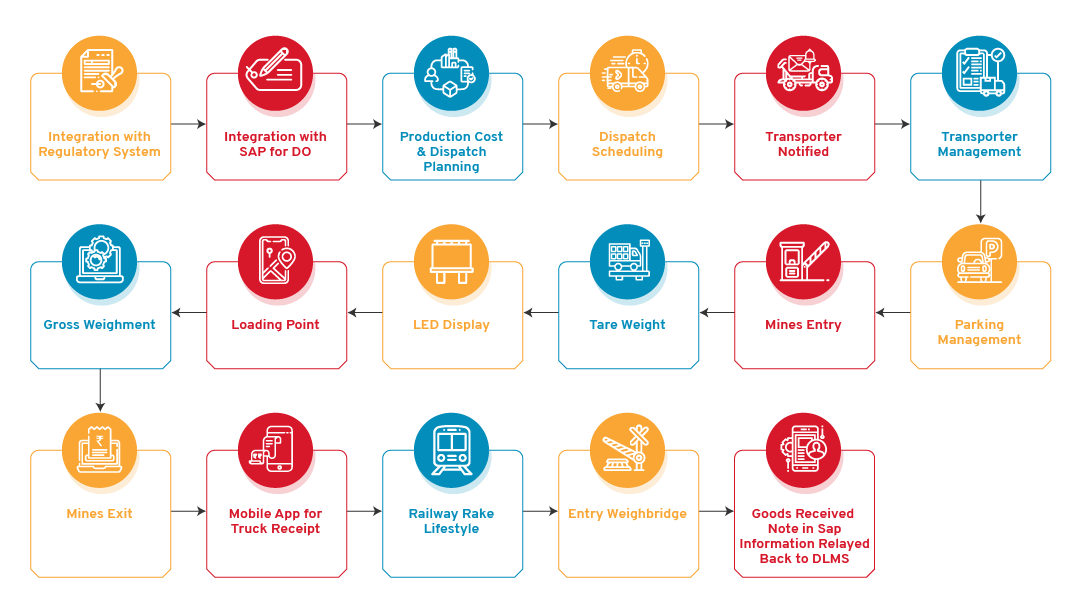

Our Seamless Digital Logistics Solution for mine value chain

CSM’s suite of multi-modal digital logistics management can break down operational silos in the mining value chain and give end-to-end visibility that enables better production planning and pit-to-port optimization, bringing in gains like higher efficiency, enhanced transparency, lower Turn Around Time (TAT), and cost optimizations with minimal human intervention.

Since May 2021, DLMS at JSW Steel has reduced truck turnaround time by 81% at critical touch points and lowered the average TAT per permit by 3 hours. This successful implementation has shown a remarkable impact on value creation, saving both time and money, while reducing weighbridge operating costs, eliminating errors, and optimizing resources, which has boosted the overall productivity of the mine-to-market value chain by 20%.

Features

- 360-degree visibility on complete in-mine and ex-mine logistics operation

- Elimination of guesswork in navigation in large mines and stockyards – thus, reduced turnaround time for mineral carriers

- Faster throughput for optimal weighbridge utilization

- Automatic identification of mineral carrying vehicles

- Seamless Integration between Hardware & Software Components (ERP, Mines & Minerals Management System, Weighbridge ecosystem)

- Centralized viewing of all inbound and outbound material

- Congestion-free operation & traffic management

Solution Components

Multi-modal digital logistics management solution includes the following major modules and areas of functionalities:

Dispatch Planning

- Plant/end-user wise dispatch planning and management of monthly plan for dispatch.

- Material requisition, mines-wise production and dispatch planning for each grade and type of ore product

- Logistics planning – for mode, route, capacity and the cost for each requisition received.

- Port terminal handling for material receipt and forward movement

- Railway siding management for material receipt and forward movement

- Monitoring of actual inventory, running permits, production, stack prepared and order fulfilment

Transporter Management

- Transporter Enumeration, profiling and vehicle profile

- Fleet & driver management

- Truck verification and vehicle-specific data such as fitness etc. through crowdsourcing and integration with third-party system

- Transporter Loading Slip tagged with the Permit and Dispatch Order

- Permit data capture from permit management system (i3MS or similar system for permit management) and Permit assignment to transporter and tagging with trip and route details (optional in case of non-miners)

- Complete visibility on permit-wise vehicle assignment and trip details

Entry and Parking Management

- Validation of driver and vehicle by security personnel against data displayed in the application

- RFID based entry of vehicle upon authentication with the Traffic light and boom barrier for access control

- Vehicle Entry permission monitoring based on capacity

- Provision for capturing ‘EMPTY OUT’ details in case of vehicle returns without load

- Parking-IN and Parking-OUT Management by verification of Transporter slip and RFID for access control inside mines/plant premise

Stack Management and Quality Control

- Monitoring stack lifecycle and management – from creation to dispatch complete visibility on permit positions and stack profile – type, grade, Maximum tolerance information for Silica, Alumina, cost implication against each stack

- Data capture for quality and grade at each stage of stack creation

- Geo-fence enabled backwards provenance tracking to pit/quarry as per plan for quality assurance

- Provision for data capture of random sampling at the time of, railway siding QC checks etc.

Unmanned weighbridge management

- Plug-and-play, fully automated module for the unassisted operation of weighbridges; due to its modular nature, unmanned weighbridge management is also a part of our other offerings such as Stockyard Management.

- IoT and Controller-based systems for reducing manpower & errors and increasing

- End-to-end tracking & monitoring of activities from Mineral production to dispatch for miners and from material receipt to dispatch for non-miners

In-mine trace and track automation

- In-mine navigation for a mineral carrier using RFID and LED display-based way finding modules

- GIS integration for locating on-field mobile assets

- Provision for GPS/LoRaWAN-based trace and track of mineral carrier in- mine and ex-mine (optional feature)

Loading point operation

- Geofence enabled loading point operations through the mobile app for supervisors

- RFID-enabled triangulated approach to ensure the right material from the right stack to the right carrier

- Confirmation by a supervisor for type, grade and stack info against the running permit

Vehicle exit and document automation management

- Automatic generation and printing of e-Transit pass post gross weighment

- SAP ERP syncing for invoice and e-way bill generation

- Provision for e-Transit Pass scanning at destination for capturing electronic proof of delivery

Railway Dispatch Management

- Siding identification, siding-wise load monitoring, despatch scheduling and siding-wise indent status identification Transporter wise notification of indent schedule and rake allotment

- Railway siding availability monitoring based on the engagement of indents

- Mobile-based, permit-wise material receipt at the railway siding (public or private)

- Near real-time visibility of dispatch progress against each permit

- Railway Rake lifecycle management starting from placement to loading to dispatch.

- In-built rake ad loading process audits from the beginning to the end.

Port Master management

- Integration with SAP ERP and port system for visibility on Bill of Lading and another document for port dispatch

- Port-wise mineral receiving, STO, stock calculation/updation and mineral assignment to the vessel

- Visibility on vessel loading status

Remote Operation Centre (ROC)

- Dedicated video wall for remote operations

- End-to-end visibility and analytics dashboard for all modules

- Real-time monitoring of fleet movement, traffic and congestion

- Alerts and notifications in case of any process deviations